Fasteners and Machining: Important Elements for Accuracy Production

Fasteners and Machining: Important Elements for Accuracy Production

Blog Article

Browsing the World of Fasteners and Machining: Strategies for Accuracy and Speed

In the intricate world of bolts and machining, the pursuit for precision and rate is a perpetual difficulty that demands careful interest to information and critical planning. From understanding the diverse variety of fastener kinds to picking optimum materials that can stand up to strenuous demands, each action in the procedure plays a critical role in achieving the desired outcome. Precision machining methods even more elevate the intricacy of this craft, needing a fragile equilibrium in between technical experience and ingenious techniques. As we explore the methods that can improve both rate and effectiveness in this domain name, the interaction between quality assurance steps and functional quality emerges as an important prime focus.

Understanding Fastener Kind

When choosing bolts for a task, recognizing the different kinds offered is critical for making certain ideal efficiency and reliability. Bolts are made use of with nuts to hold materials with each other, while screws are versatile bolts that can be made use of with or without a nut, depending on the application. Washers are necessary for dispersing the tons of the bolt and protecting against damage to the material being secured.

Choosing the Right Products

Understanding the importance of selecting the appropriate products is critical in ensuring the ideal efficiency and integrity of the selected bolt types discussed previously. When it comes to bolts and machining applications, the product selection plays an essential duty in determining the general toughness, sturdiness, deterioration resistance, and compatibility with the designated setting. Various materials provide varying residential or commercial properties that can substantially influence the performance of the bolts.

Typical materials used for bolts consist of steel, stainless-steel, titanium, brass, and aluminum, each having its unique strengths and weaknesses. Steel is renowned for its high stamina and sturdiness, making it appropriate for a variety of applications. Stainless steel provides outstanding deterioration resistance, ideal for atmospheres susceptible to moisture and chemicals. Light weight aluminum is corrosion-resistant and light-weight, making it appropriate for applications where weight decrease is crucial. Brass is commonly chosen for its visual allure and exceptional conductivity. Titanium is understood for its outstanding strength-to-weight proportion, making it optimal for high-performance applications. Selecting the ideal material includes taking into consideration aspects such as strength demands, environmental problems, and budget constraints to guarantee the preferred performance and longevity of the bolts.

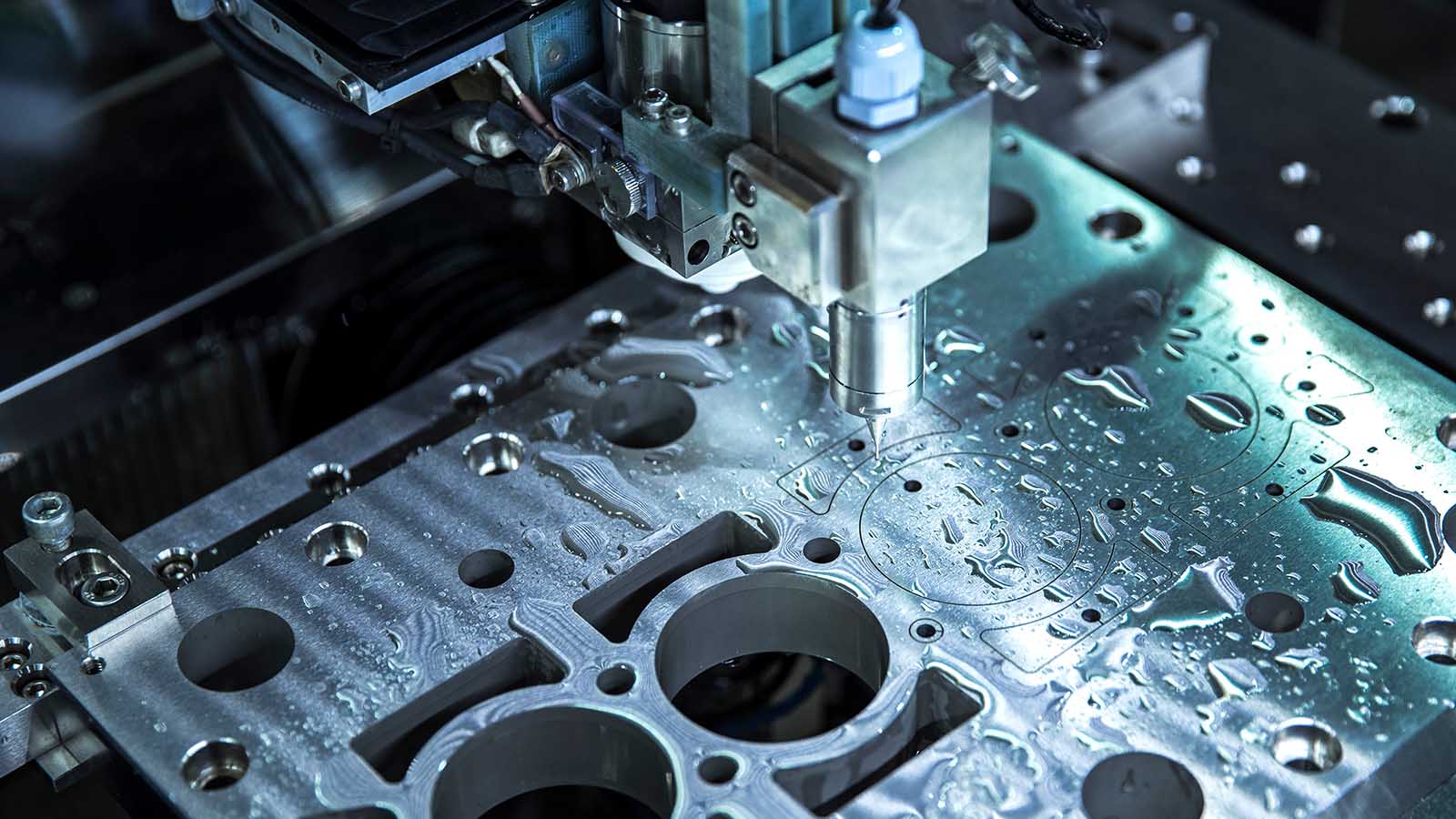

Precision Machining Techniques

Along with CNC machining, various other precision strategies like grinding, transforming, milling, and boring play crucial functions in fastener manufacturing. Grinding assists accomplish fine surface area coatings and limited dimensional resistances, while transforming is usually made use of to develop cylindrical components with precise sizes. Milling and drilling click for more procedures are essential for forming and developing holes in bolts, guaranteeing they satisfy precise specs and function properly.

Enhancing Rate and Performance

To maximize bolt production procedures, it is crucial to improve procedures and execute effective approaches that match precision machining methods. Automated systems can take care of recurring tasks with precision and YOURURL.com speed, permitting workers to concentrate on more complicated and value-added tasks. By incorporating these techniques, manufacturers can accomplish a balance between rate and precision, inevitably boosting their affordable edge in the bolt sector.

Top Quality Control Steps

Applying rigorous quality control steps is vital in guaranteeing the reliability and consistency of bolt products in the manufacturing procedure. Quality assurance procedures encompass various phases, beginning from the selection of basic materials to the final examination of the finished bolts. One fundamental element of quality control is performing complete product inspections to validate compliance with specs. This entails assessing aspects such as product toughness, make-up, and stamina to guarantee that the fasteners fulfill market requirements. In addition, keeping track of the machining refines is necessary to support dimensional precision and surface coating high quality. Making use of advanced modern technology, such as automated examination systems and accuracy measuring tools, can enhance the accuracy and effectiveness of quality control treatments.

Normal calibration of devices and equipment is vital to preserve uniformity in production and make certain that fasteners satisfy the needed resistances. Applying rigorous procedures for determining and resolving non-conformities or issues is essential in preventing substandard products from entering the marketplace. By establishing a thorough quality assurance framework, makers can copyright the credibility of their brand and deliver fasteners that satisfy the highest possible requirements of efficiency and sturdiness.

Verdict

In the elaborate realm of bolts and machining, the mission for precision and rate is a continuous difficulty that demands careful attention to information and tactical preparation. When it comes to fasteners and machining applications, the material selection plays a critical function in determining the general strength, sturdiness, deterioration resistance, and compatibility with the intended environment. Precision machining entails different innovative blog techniques that ensure the limited tolerances and specifications needed for bolts.In enhancement to CNC machining, various other accuracy methods like grinding, transforming, milling, and exploration play crucial roles in fastener production.To optimize fastener production processes, it is important to streamline operations and apply reliable strategies that complement accuracy machining strategies.

Report this page